TEAM

Team of 25 members

TOOLS

AutoCAD, SketchUp, Photoshop CC

TIMELINE

Nov 2019

LOCATION

Islamnagar Village, Bhopal

AWARDS

Shortlisted Top 60 (National)

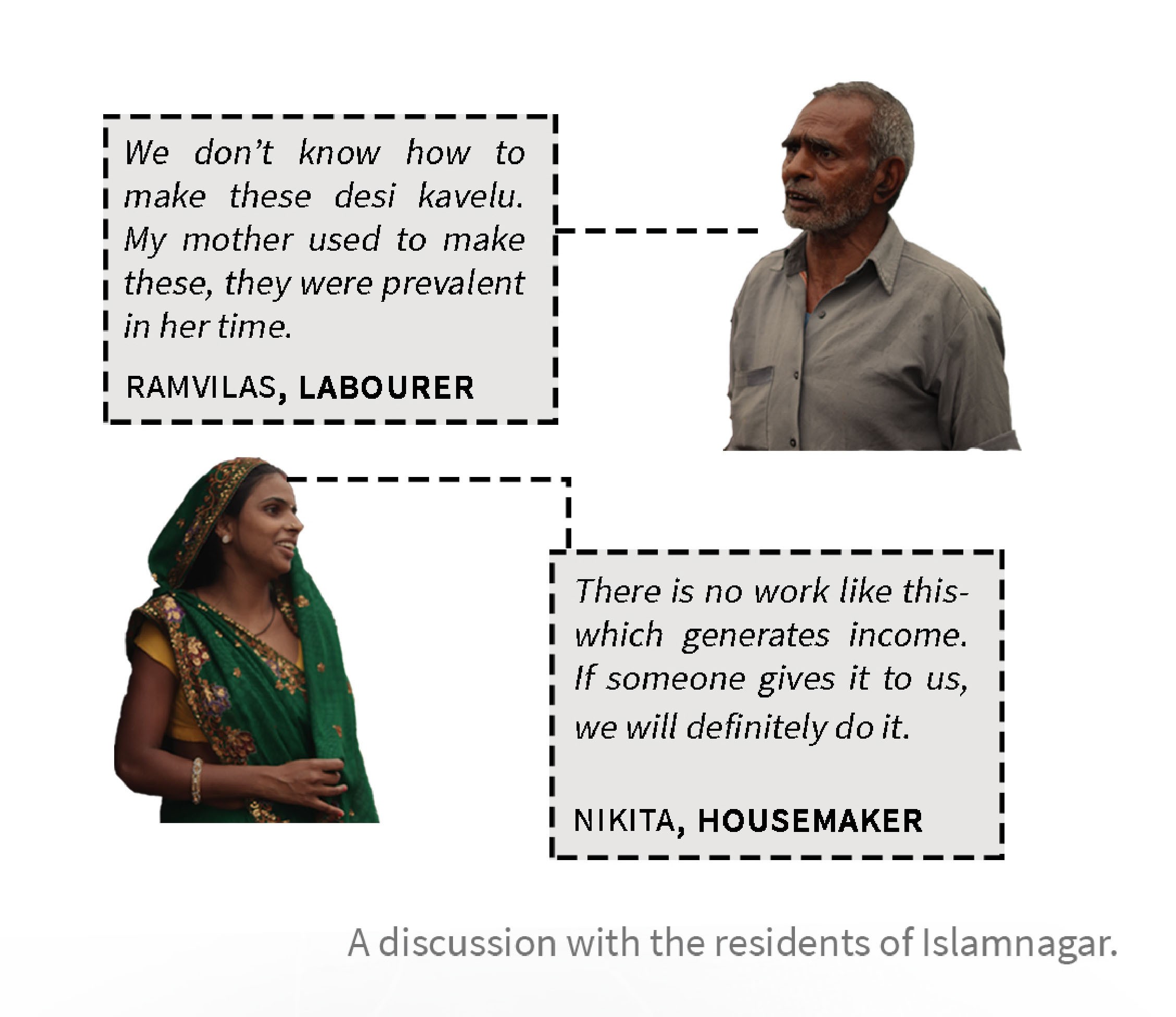

Reviving the forgotten traditions, learning from past mistakes, perceiving habitats differently, and embarking on an introspective future by blending together modernity with tradition. This is the essence of the design concept. Reviving the forgotten traditions, we try to embark on a future where habitat is perceived not as a finished product, but as a process from which its inhabitants can benefit economically and socially.

ISLAMNAGAR, BHOPAL

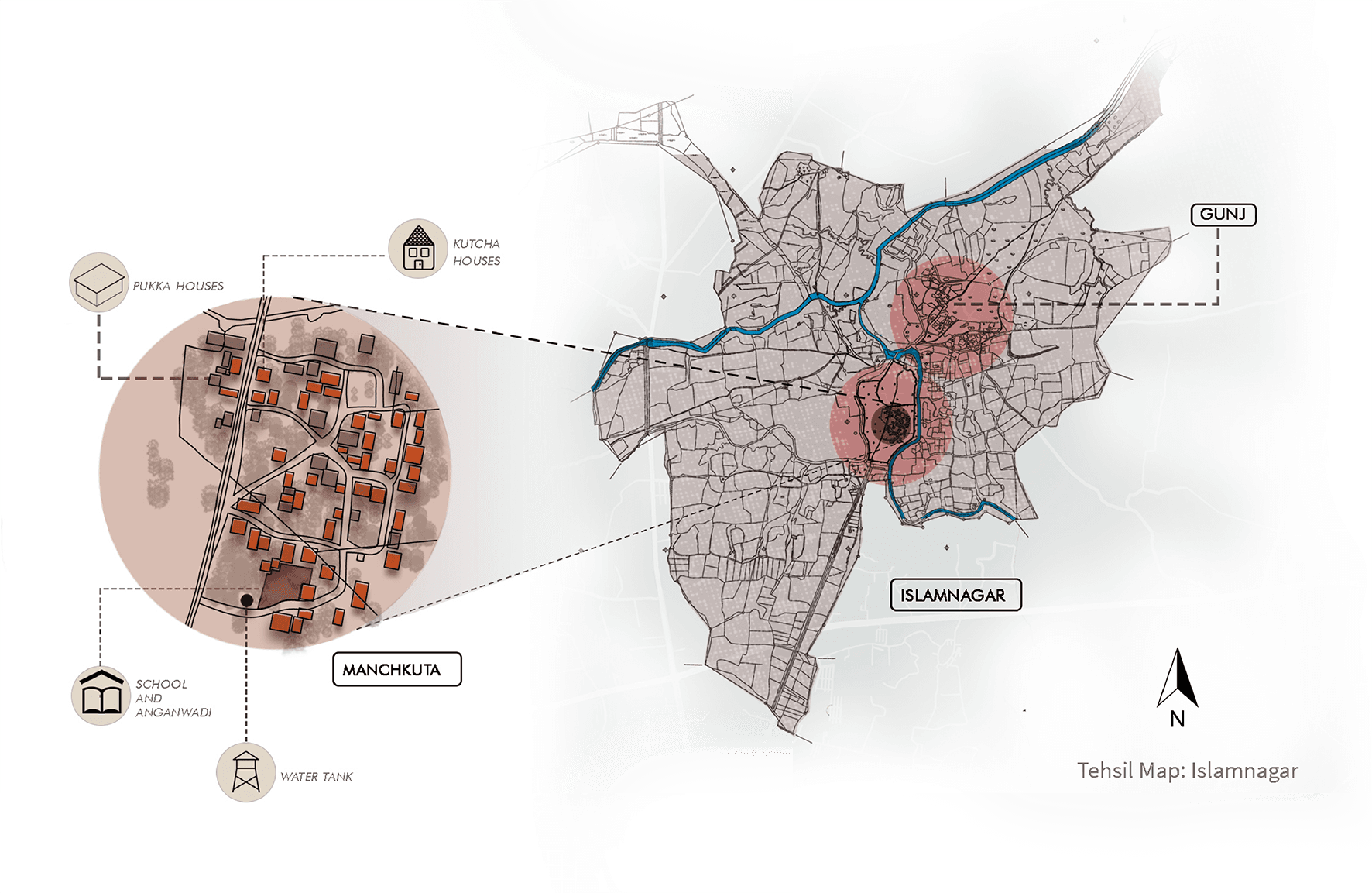

The fortified city of Islamnagar, originally called Jagdishpura, is a panchayat-governed region in the Huzur tehsil of the Bhopal district of Madhya Pradesh. Hitherto it was the capital of the Bhopal princely state. Linked to Bhopal by a state highway, the village is approximately 11 kilometers away from it.

The village has a population of 3638 people residing in 724 households.

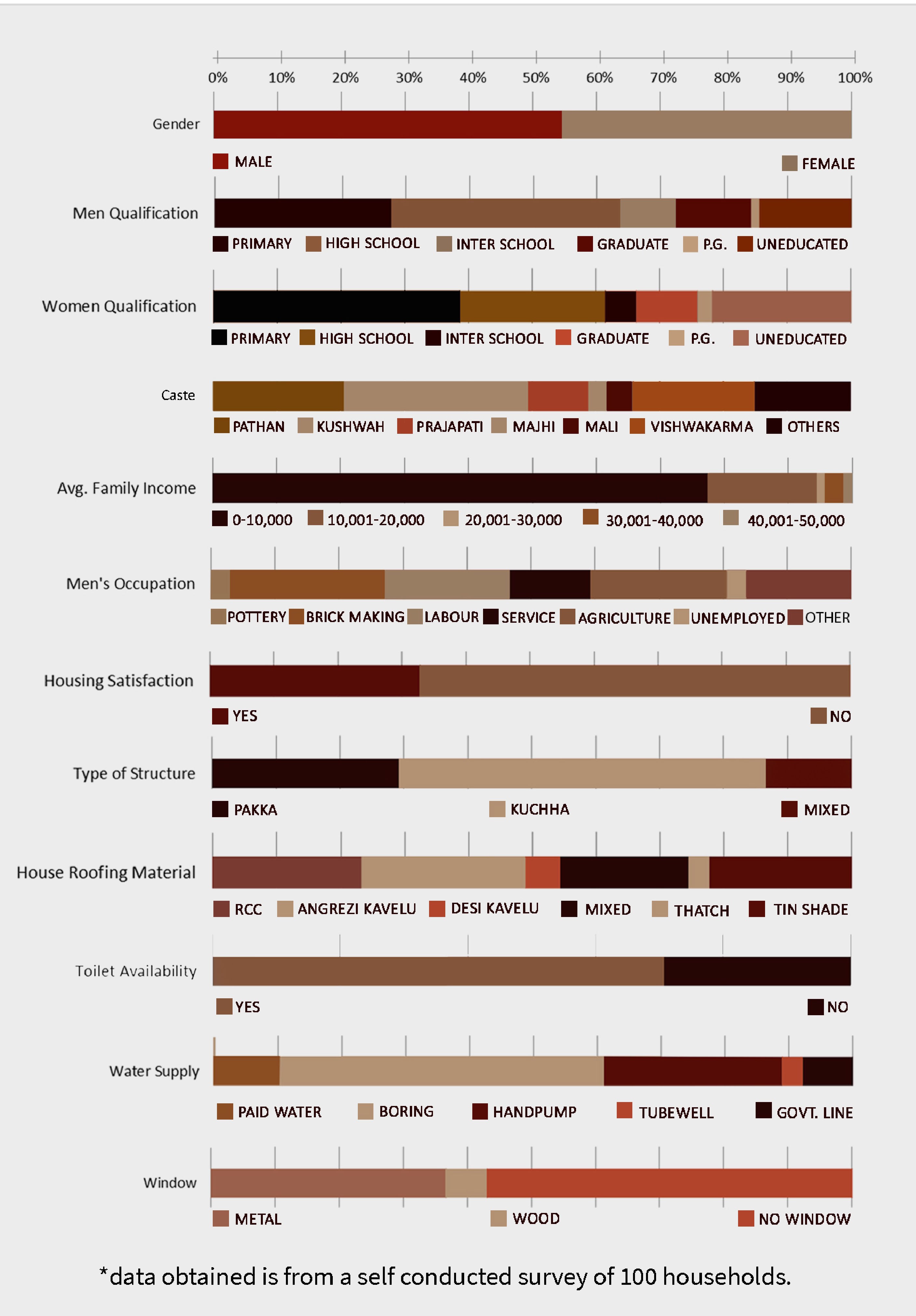

To understand the site and its context more, we conducted structured surveys of 100 households asking questions about housing conditions, qualifications, and occupations.

HOUSING CONDITION

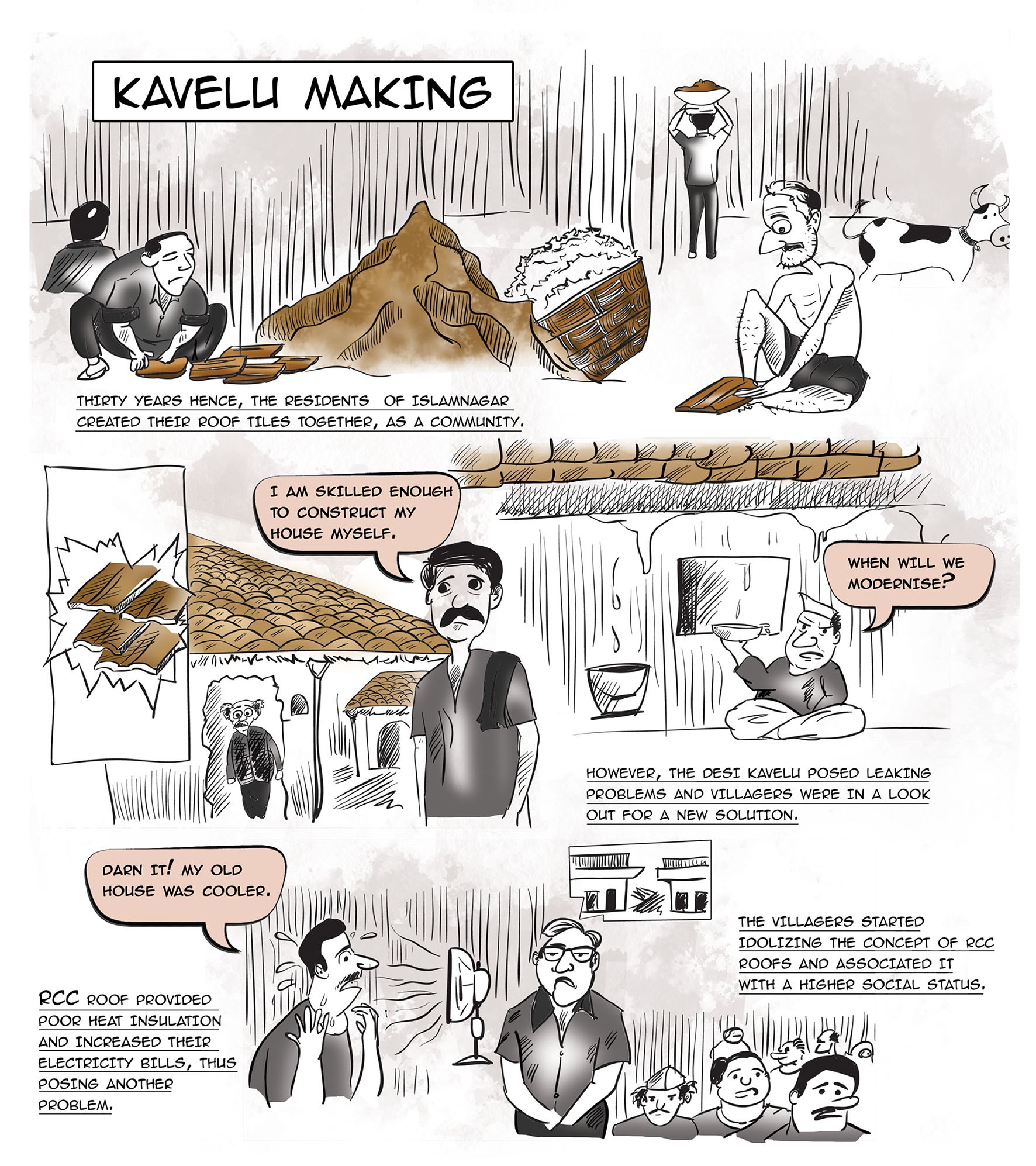

The village houses feature roofs made of locally crafted desi or factory-made angrezi kavelu clay tiles.

The village comprises of two types of houses: kutcha and pakka. The kutcha houses are one storied with walls of mud, stone and mud or brick and mud. The roofing material for kutcha houses is mainly desi or angrezi kavelu (locally made or factory-made clay tiles). The windows, if present, are either made of wood or metal. The pakka houses are made of brick and concrete walls with RCC roofs.

Most of the dwellings had toilets, either attached or at some distance. There was electricity supply in every house powering lightbulbs, fans and in some cases, coolers and TV.

MANCHKUTA - THE VILLAGE SECTION

SOCIAL PRODUCTION PROCESSES OF THE VILLAGE

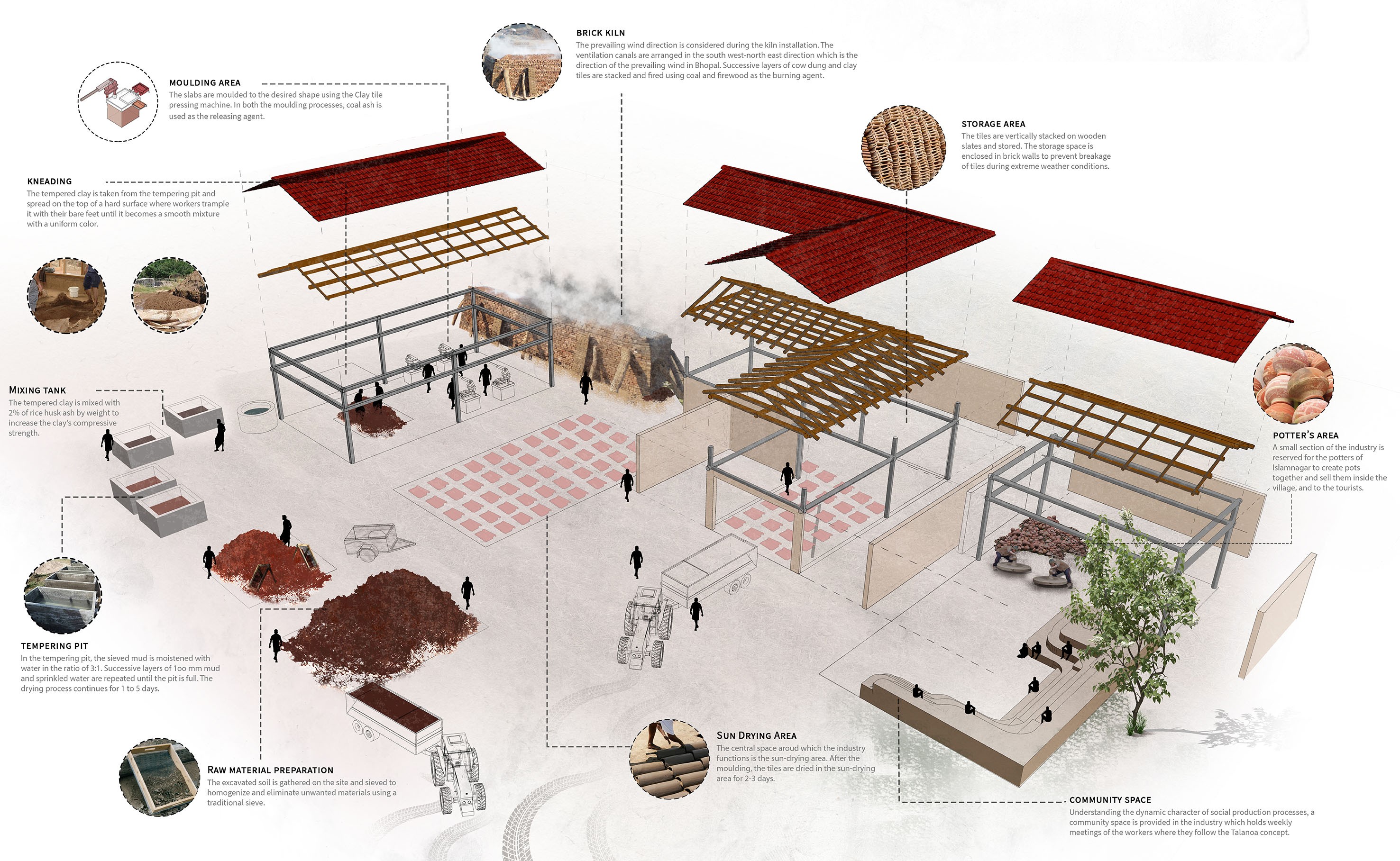

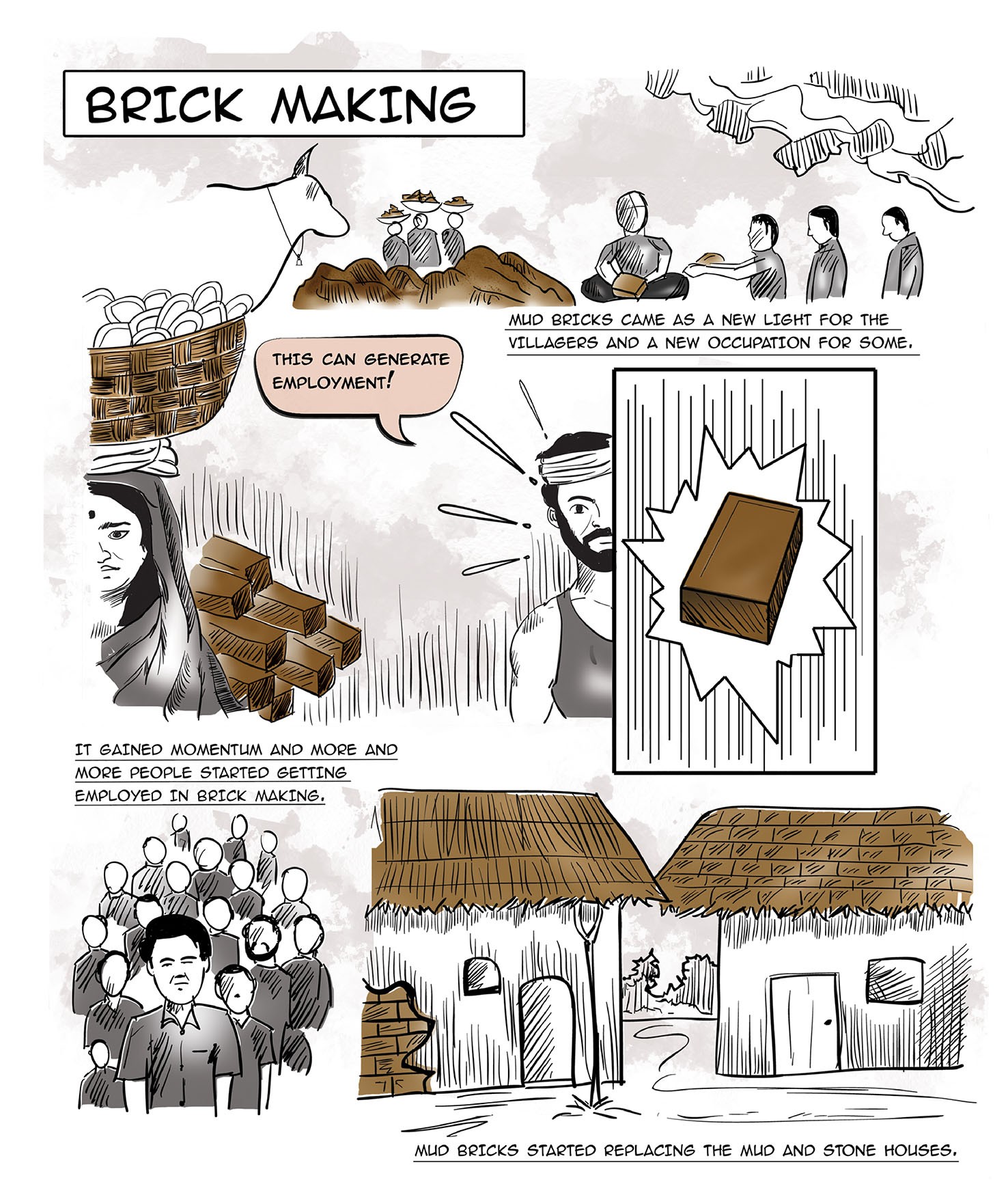

The Brick Making Process

The Kumhaar community is involved in the brick making process which generates employment for them and housing solutions for the village. The process involves 8 months of labour and no work is done during the monsoon season. The bricks are sun-dried and then burnt in traditional kilns to make the brick firm.

ELEMENTS OF THE SOCIAL PRODUCTION PROCESSES

Mud

It forms an essential component of Kavelu and brick manufacturing mud having appropriate clay content is bought from nearby areas or procured locally.

Rice Husk

Addition of rice husk in the mud mixture and increases water absorption compressive strength of mud and helps in binding the bricks.

Cow Dung

Cowdung is used in the traditional kilns as a potent organic fuel. Alternative layers of brick and cowdung cake are burnt in kilns.

Coal and Ash

Coal is the conventional kiln fuel, important to keep the furnace stimulated throughout the process. After the process, pulverized fuel ash appears as the combustion product.

Kavelu Skill

A number of people possess the requisite finesse in Kavelu manufacturing.

THE KAVELU PROBLEM

Although the new factory-produced tiles (Angrezi Kabelu) manage to solve the issues of leakage, breakage and moss formation posed by locally-produced tiles (Desi Kabelu), they are expensive and have rendered the women of the vilage jobless. The import of foreign tiles has also hampered the traditional village economy.

WHY SOLVE THIS PROBLEM?

HALF PILLAR TAILOR TILES

Changes are made in the old kavelu design to solve problems of water leakage moss and breakage.

A semi-circular interlocking system is added to the conventional Mangalore tile design for higher interlocking and lesser leakage during rainfall. The addition of grooves on consecutive sides help in upward and sideward interlocking. These types of tiles are called Half Pillar Tailor tiles and are prevalent in Gujarat.

Small sizes require a greater number of blocks per cubic metre than larger ones, so the overall effort needed to produce small blocks is greater than that of making larger ones.

Thus, the size chosen is 16" * 10".

AN IMPROVISED KAVELU

Rice husk ash when added to the conventional Kavelu tiles replaced the space in the product, decreasing the density and the compressive strength of the desi kavelu. Thus, the conventional rice husk is replaced by rice husk ash. The ideal amount of rice husk ash by weight is found to be 2 percent.

Rice husk is locally available in the village and is a by-product of rice mills located at Gunj section of Islamnagar. The moss can be prevented by applying a coat of water-proof adhesive diluted with water in the ratio of 3:7 on the terracotta tiles.

HOUSE ROOFING MODELS